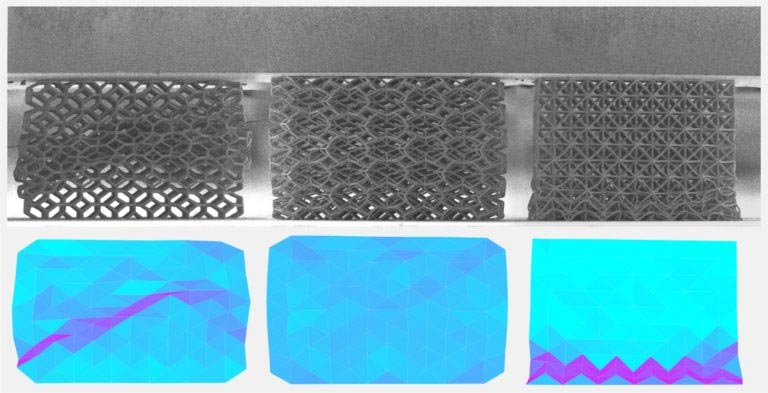

Novel tensegrity metamaterials by UCI and Georgia Institute of Technology scientists use separated compressive loop aspects that are specifically linked through a constant network of tensile members (highlighted in magenta). Credit: Jens Bauer and Cameron Crook / UCI

Study demonstrates how century-old style concept can be a path to conquering failure.

Catastrophic collapse of products and structures is the inescapable effect of a domino effect of in your area restricted damage – from strong ceramics that snap after the advancement of a little fracture to metal area trusses that pave the way after the warping of a single strut.

In a research study released today in Advanced Materials, engineers at the University of California, Irvine and the Georgia Institute of Technology explain the production of a brand-new class of mechanical metamaterials that delocalize contortions to avoid failure. They did so by relying on tensegrity, a century-old style concept in which separated stiff bars are incorporated into a versatile mesh of tethers to produce really light-weight, self-tensioning truss structures.

Starting with 950 nanometer-diameter members, the group utilized an advanced direct laser composing strategy to produce primary cells sized in between 10 and 20 microns. These were developed into eight-unit supercells that might be put together with others to make a constant structure. The scientists then carried out computational modeling and lab experiments and observed that the constructs displayed distinctively homogenous contortion habits devoid of localized overstress or underuse.

The group revealed that the brand-new metamaterials include a 25-fold improvement in deformability and an orders-of-magnitude boost in energy absorption over advanced lattice plans.

In a contrast with 2 other advanced nanoscale structures, the tensegrity lattice developed by UCI and Georgia Tech scientists (center) displayed a 25-fold enhancement in deformability and an orders-of-magnitude boost in energy absorption. Jens Bauer and Cameron Crook / UCI

“Tensegrity structures have been studied for decades, particularly in the context of architectural design, and they have recently been found in a number of biological systems,” stated senior co-author Lorenzo Valdevit, a UCI teacher of products science and engineering who directs the Architected Materials Group. “Proper periodic tensegrity lattices were theoretically conceptualized only a few years ago by our co-author Julian Rimoli at Georgia Tech, but through this project we have achieved the first physical implementation and performance demonstration of these metamaterials.”

While establishing structural setups for planetary landers, the Georgia Tech group found that tensegrity-based automobiles might stand up to extreme contortion, or buckling, of its private elements without collapsing, something never ever observed in other structures.

“This gave us the idea of creating metamaterials that exploit the same principle, which led us to the discovery of the first-ever 3D tensegrity metamaterial,” described Rimoli, aerospace engineering teacher at Georgia Tech.

Made possible by unique additive production methods, exceptionally light-weight yet strong and stiff standard structures based upon micrometer-scale trusses and lattices have actually been of eager interest to engineers for their prospective to change much heavier, strong compounds in airplane, wind turbine blades and a host of other applications. Though having numerous preferable qualities, these sophisticated products can – like any load-bearing structure – still be prone to disastrous damage if strained.

“In familiar nano-architected materials, failure usually starts with a highly localized deformation,” stated very first author Jens Bauer, a UCI research study researcher in mechanical and aerospace engineering. “Shear bands, surface cracks, and buckling of walls and struts in one area can cause a chain reaction leading to the collapse of an entire structure.”

He described that truss lattices start to collapse when compressive members buckle, considering that those in stress cannot. Typically, these parts are adjoined at typical nodes, suggesting that when one stops working, damage can rapidly spread out throughout the whole structure.

In contrast, the compressive members of tensegrity architectures form closed loops, separated from one another and just linked by tensile members. Therefore, instability of compressive members can just propagate through tensile load courses, which – supplied they do not burst – cannot experience instability. Push down on a tensegrity system and the entire structure compresses consistently, avoiding localized damage that would otherwise trigger disastrous failure.

According to Valdevit, who’s likewise a teacher of mechanical and aerospace engineering at UCI, tensegrity metamaterials show an extraordinary mix of failure resistance, severe energy absorption, deformability and strength, exceeding all other kinds of advanced light-weight architectures.

“This study provides important groundwork for design of superior engineering systems, from reusable impact protection systems to adaptive load-bearing structures,” he stated.

Reference: “Tensegrity Metamaterials: Toward Failure‐Resistant Engineering Systems through Delocalized Deformation” by Jens Bauer, Julie A. Kraus, Cameron Crook, Julian J. Rimoli and Lorenzo Valdevit, 5 February 2021, https://doi.org/10.1002/adma.202005647.

DOI: 10.1002/adma.202005647

Julie Kraus, a college student in the Rimoli lab at Georgia Tech, took part in this research study, as did Cameron Crook, a UCI college student in products science and engineering. Funding was offered by NASA and the National Science Foundation.