By

$ 2.5 trillion is invested worldwide to evaluate, reduce and fix deterioration of facilities, according to Penn State Assistant Professor Juan PabloGevaudan He is leading a group examining how to avoid his prevalent destruction.

Metals ingrained in concrete can wear down, rusting, and deteriorating till the concrete divides and the structure it supports falls. Such deterioration is thought to be among the primary concerns that worsened the damage that caused the June 24, 2021, Surfside, Florida, condo collapse, according to the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST).

This deterioration is among the greatest international resilience obstacles throughout facilities in all fields, according to Juan Pablo “JP” Gevaudan, assistant teacher of architectural engineering and primary private investigator of a three-year, $800,000 grant from the U.S. Department of Energy’s (DOE) Nuclear Energy University Program that will even more check out the electrochemical deterioration destruction science of concrete as it uses to top-level hazardous waste (HLNW).

Defined by the DOE as any radioactive product that needs irreversible seclusion, HLNW can arise from processing nuclear fuel and produce radionuclides, radioactive atoms that are naturally unsteady and damaging to life. Currently, HLNW is packaged in metal cylinders and ingrained in concrete. Gevaudan’s partners consist of Andrea Arg üelles, assistant teacher of engineering science and mechanics, and Rebecca Napolitano, assistant teacher of architectural engineering.

“Understanding and preventing corrosion — especially in infrastructure — is one of our great global durability challenges,” Gevaudan stated. “The degradation science of concrete applies to many engineering fields, and we all want to improve our infrastructure.”

According to Gevaudan, when he and his partners discovered of the obstacles at the end-of-life of nuclear fuel cycles, they right away saw synergy in between architectural engineering’s objective of enhancing the resilience of the constructed environment with the DOE’s objective of studying deterioration in ingrained HLNW metal cylinders to extend the life span of the hazardous waste disposal facilities. To broaden this synergy throughout University Park, Gevaudan stated, the group has actually currently met professors in the Ken and Mary Alice Lindquist Department of Nuclear Engineering to determine locations where their work might line up, and they prepare to continue their conversations on locations of convergent research study.

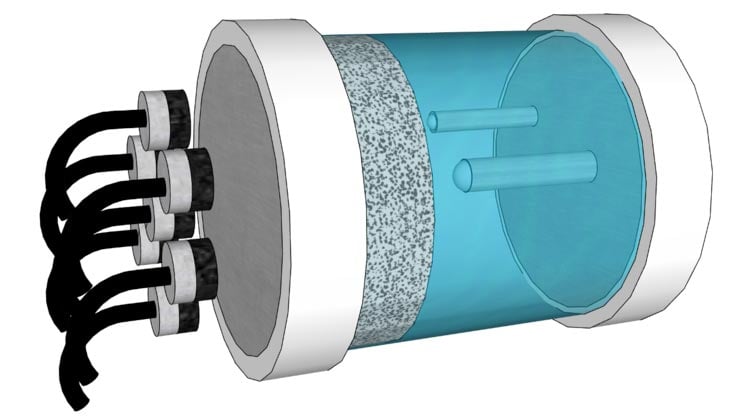

The research study group led by Gevaudan crafted the first-ever combined ultrasound-electrochemical impedance spectroscopy gadget, called UT-EIS, to non-destructively asses the deterioration resistance in between brand-new cement buffer products and top-level hazardous waste cylinders. Credit: Penn State/Juan Pablo Gevaudan

“In this unique project, our goal is to create a new material that can protect the HLNW metal canisters, which contain the waste byproducts of reactions that occur in nuclear reactors,” Gevaudan stated. “We hope we will develop a new cement-based buffer material that can immobilize harmful radionuclides that, in a critical situation, might leak from the HLNW canisters and keep the waste from reaching the environment and humans — which would be a catastrophe.”

For this task, Gevaudan will take advantage of current advances by his research study group, the Responsive and Adaptive Infrastructure Materials (Re- GOAL) research study group, using natural and inorganic chemistry interactions to establish exactly created, modern-day concrete products. To anticipate destruction in time of these brand-new buffer products, Napolitano will produce digital twins of systems to design proposed options and test prospective results. Arg üelles will use ultrasonic screening of the metal user interface in a bespoke plan to non-destructively evaluate the deterioration capacity of various buffer product solutions. Together, the group prepares to invest the very first 18 months of the grant duration, which begins in October, establishing a concrete that can bind damaging waste dripping from a reactor’s metal cylinder. During the 2nd 18 months, they prepare to enhance the buffer product to assist avoid the metal cylinder from wearing away in the very first location.

“It is said that reinforcement steel and concrete are best friends,” Gevaudan stated. “The microstructural properties of concrete allow the steel to develop a passive layer, a kind of protective shell that protects it from corrosion — but it can break down due to age or environmental aggressors. The material we are developing will create a passive layer that will prevent corrosion over thousands to, potentially, millions of years.”

To assistance attain a lasting, reliable product, Gevaudan stated, the group is acquiring an automated reactor from Mettler Toledo, a business that produces accuracy instruments for a variety of fields. With the reactor, the scientists can manufacture modern-day cement products with preferred homes in exactly regulated conditions with high repeatability. The device likewise assists track the stages formed in the brand-new cements, which enables the scientists for more information about particular mineral setups that develop as the cementitious product is developed.

“We’ll be able to quickly identify which phase best binds radionuclides of interest, which will help us fast-track the development of the material,” Gevaudan stated. “This grant allowed us to bring this advanced technology to cement research, which has traditionally used methodologies stuck in the past.”

The grant will likewise assist fund trainee scientists to deal with the task as they finish their degrees in architectural engineering, chemical engineering, engineering science and mechanics and acoustics, in addition to other associated disciplines. Gevaudan stated the group prepares to grow and has a particular interest in trainees who are generally underrepresented in engineering and are pursuing academic degrees.

“Besides the science, one of the most-rewarding aspects about this project is building our team,” Gevaudan stated. “This project symbolizes a group effort led by three early-career faculty members who are all underrepresented in engineering. We worked hard to earn this grant, and I’m proud of the work we have done and will continue to do to work across disciplines to prevent steel corrosion — one of the most pervasive degradation challenges we have.”