A green approach for producing crystalline supramolecular fibers assures to make polymer production more sustainable.

A polymer that catalyzes its own development in an eco-friendly solvent-free procedure has actually been established by an all-RIKEN group of chemists. The discovery might cause the advancement of naturally recyclable polymer products that are used a sustainable procedure.

Polymers are common today, however they are harmful to the environment through the build-up of plastic waste and the unsustainable nature of traditional polymer manufacture. Polymers are normally made by connecting together strings of foundation, referred to as monomers, utilizing covalent bonds. But these strong bonds make it tough to take utilized, end-of-life plastic products and de-polymerize them to recuperate the monomers for reuse.

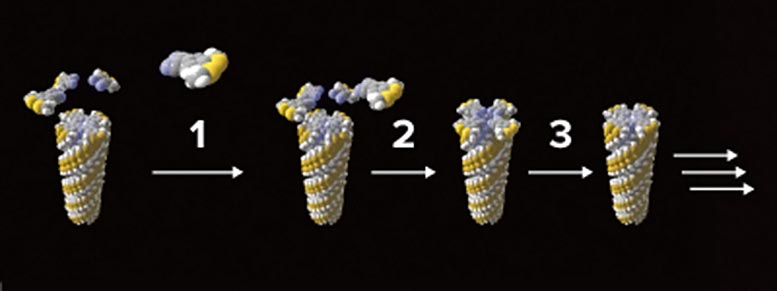

Figure 1: Wedge- formed precursor particles (leading left) come together to construct a rod-shaped supramolecular polymer made up of their reductively cyclotetramerized disk-shaped monomers, with each brand-new layer of the growing polymer templating the development of the next (1 and 2 reveal the preorganization of wedge-shaped precursor phthalonitrile particles, and 3 programs reductive cyclotrimerization to offer a disk-shaped phthalocyanine monomer). Credit: © 2022 RIKEN Center for Emergent Matter Science

Supramolecular polymers, on the other hand, include varieties of monomers held together by interactions such as hydrogen bonds, which are weaker, and for this reason more reversible, than covalent bonds.

However, the solvents utilized for making supramolecular polymers restrict their application and sustainability. “Within two decades, solvent-free chemical manufacturing may be the only approved chemical processes, since the large volumes of solvent used in other manufacturing processes are too damaging to the environment,” states Takuzo Aida from the RIKEN Center for Emergent Matter Science (CEMS).

Aida’s group has actually been examining wedge-shaped particles called phthalonitriles. Now, he and 9 CEMS associates have actually found that these compounds melt when heated up and after that form numerous thin green crystalline fibers, which are rod-shaped supramolecular polymers.

The polymerization procedure is started when 4 of the wedge-shaped pieces come together to form a flat, circular disk. The disk-shaped assembly– the monomer– can then serve as a design template surface area for the next 4 wedge-shaped precursor particles to integrate, including a layer to the structure. This procedure is duplicated, with each brand-new layer of the polymer catalyzing the development of the next, up until long rod-like structures form (Figure 1). The group called their procedure solvent-free autocatalytic supramolecular polymerization.

“The mechanical properties of the crystalline fibers of these supramolecular polymers are analogous to those of poly(alkyl methacrylates),” Aida states. These traditional polymers are utilized for a variety of applications, consisting of plexiglass.

The group might produce more intricate variations of their supramolecular polymers by including alternate precursor particles into the mix at particular time points, therefore forming ‘block copolymers’ with bands of various monomers along the length of each rod.

Solvent- totally free autocatalytic supramolecular polymerization might be utilized to make supramolecular polymers from a variety of beginning products. “It may be applicable to the synthesis of polycyclic aromatic hydrocarbons and cyclic peptides,” Aida states.

Reference: “Solvent-free autocatalytic supramolecular polymerization” by Zhen Chen, Yukinaga Suzuki, Ayumi Imayoshi, Xiaofan Ji, Kotagiri Venkata Rao, Yuki Omata, Daigo Miyajima, Emiko Sato, Atsuko Nihonyanagi and Takuzo Aida, 14 October 2021, Nature Materials

DOI: 10.1038/ s41563-021-01122- z