Rice University chemical engineering college student Siraj Sidhik holds a container of 2D perovskite “seeds” (left) and a smaller sized vial consisting of a service of liquified seeds that can be utilized to produce thin movies for usage in extremely effective optoelectronic gadgets like high performance photovoltaic panels. Credit: Photo by Jeff Fitlow/Rice University

Engineers produce seeds for growing near-perfect 2D perovskite crystals.

Rice University engineers have actually produced tiny seeds for growing extremely consistent 2D perovskite crystals that are both steady and extremely effective at gathering electrical power from sunshine.

Halide perovskites are natural products made from plentiful, economical components, and Rice’s seeded development technique addresses both efficiency and production concerns that have actually kept back halide perovskite photovoltaic innovation.

In a research study released online in Advanced Materials, chemical engineers from Rice’s Brown School of Engineering explain how to make the seeds and utilize them to grow homogenous thin movies, extremely looked for products consisted of consistently thick layers. In lab tests, photovoltaic gadgets made from the movies showed both effective and trustworthy, a formerly bothersome mix for gadgets made from either 3D or 2D perovskites.

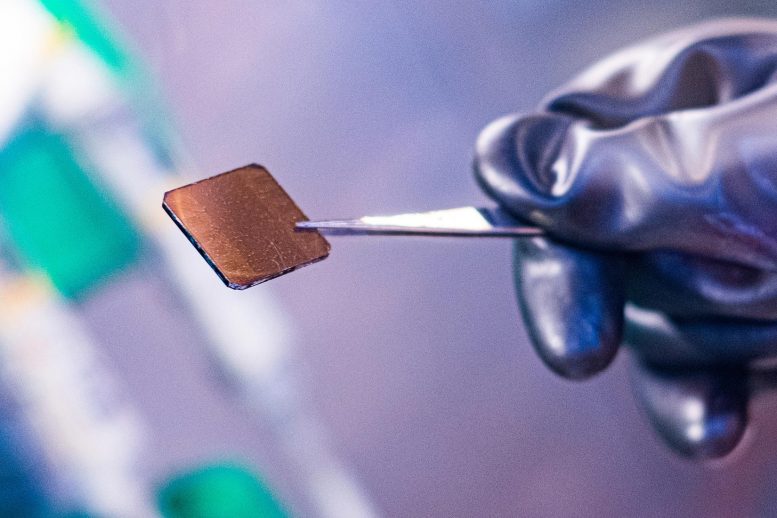

A thin movie of 2D halide perovskite crystals of consistent density. Rice engineers found a self-assembly technique for producing the movies from “seeds,” submicroscopic pieces of 2D crystals that act as design templates. Credit: Photo by Jeff Fitlow/Rice University

“We’ve come up with a method where you can really tailor the properties of the macroscopic films by first tailoring what you put into solution,” stated research study co-author Aditya Mohite, an associate teacher of chemical and biomolecular engineering and of products science and nanoengineering at Rice. “You can arrive at something that is very homogeneous in its size and properties, and that leads to higher efficiency. We got almost state-of-the-art device efficiency for the 2D case of 17%, and that was without optimization. We think we can improve on that in several ways.”

Mohite stated attaining homogenous movies of 2D perovskites has actually been a substantial obstacle in the halide perovskite photovoltaic research study neighborhood, which has actually grown significantly over the previous years.

“Homogeneous films are expected to lead to optoelectronic devices with both high efficiency and technologically relevant stability,” he stated.

Rice University engineering college student Mohammad Samani (left) and Siraj Sidhik found a seeded-growth technique for producing 2D halide perovskite thin movies with layers of consistent density. Homogeneous 2D perovskite movies have actually been extremely looked for and are anticipated to cause photovoltaic panels and other extremely effective and steady optoelectronic gadgets. Credit: Photo by Jeff Fitlow/Rice University

Rice’s seed-grown, high-efficiency photovoltaic movies showed rather steady, protecting more than 97% of their peak performance after 800 hours under lighting with no thermal management. In previous research study, 3D halide perovskite photovoltaic gadgets have actually been extremely effective however susceptible to fast deterioration, and 2D gadgets have actually done not have performance however were extremely steady.

The Rice research study likewise information the seeded development procedure — an approach that is within the reach of lots of laboratories, stated research study co-author Amanda Marciel, a William Marsh Rice Trustee Chair and assistant teacher of chemical and biomolecular engineering at Rice.

“I think people are going to pick up this paper and say, ‘Oh. I’m going to start doing this,’” Marciel stated. “It’s a really nice processing paper that goes into depth in a way that hasn’t really been done before.”

Aditya Mohite is an associate teacher of chemical and biomolecular engineering and of products science and nanoengineering at Rice University. Credit: Jeff Fitlow/Rice University

The name perovskite refers both to a particular mineral found in Russia in 1839 and to any substance with the crystal structure of that mineral. For example, halide perovskites can be made by blending lead, tin and other metals with bromide or iodide salts. Research interest in halide perovskites increased after their capacity for high-efficiency photovoltaics was shown in 2012.

Mohite, who signed up with Rice in 2018, has actually looked into halide perovskite photovoltaics for more than 5 years, specifically 2D perovskites — flat, nearly atomically thin types of the product that are more steady than their thicker cousins due to an intrinsic wetness resistance.

Amanda Marciel. Credit: Photo by Jean Lachat

Mohite credited research study co-lead author Siraj Sidhik, a Ph.D. trainee in his laboratory, with the concept of pursuing seeded development.

“The idea that a memory or history — a genetic sort of seed — can dictate material properties is a powerful concept in materials science,” Mohite stated. “A lot of templating works like this. If you want to grow a single crystal of diamond or silicon, for example, you need a seed of a single crystal that can serve as template.”

While seeded development has actually frequently been shown for inorganic crystals and other procedures, Mohite stated this is the very first time it’s been displayed in natural 2D perovskites.

The procedure for growing 2D perovskite movies from seeds equals in a number of aspects to the classical procedure of growing such movies. In the conventional technique, precursor chemicals are distributed like the components in a kitchen area — X parts of component A, Y parts of component B, and so on — and these are liquified in a liquid solvent. The resulting option is spread out onto a flat surface area through spin-coating, an extensively utilized strategy that counts on centrifugal force to equally spread out liquids throughout a quickly spun disk. As the solvent liquifies, the blended components crystalize in a thin movie.

Mohite’s group has actually made 2D perovskite movies in this way for several years, and though the movies appear completely flat to the naked eye, they are unequal at the nanometer scale. In some locations, the movie might be a single crystal in density, and in other locations, a number of crystals thick.

“You end up getting something that is completely polydisperse, and when the size changes, the energy landscape changes as well,” Mohite stated. “What that means for a photovoltaic device is inefficiency, because you lose energy to scattering when charges encounter a barrier before they can reach an electrical contact.”

In the seeded development technique, seeds are made by slow-growing a uniform 2D crystal and grinding it into a powder, which is liquified into solvent rather of the private precursors. The seeds consist of the exact same ratio of components as the classical dish, and the resulting option is spin-coated onto disks precisely as it would be in the initial technique. The evaporation and formation actions are likewise similar. But the seeded option yields movies with an uniform, consistent surface area, just like that of the product from which the seeds were ground.

When Sidhik at first prospered with the method, it wasn’t instantly clear why it produced much better movies. Fortunately, Mohite’s laboratory adjoins Marciel’s, and while she and her trainee, co-lead author Mohammad Samani, had actually not formerly dealt with perovskites, they did have the best tool for finding and studying any littles undissolved seeds that may be templating the uniform movies.

“We could track that nucleation and growth using light-scattering techniques in my group that we typically use to measure sizes of polymers in solution,” Marciel stated. “That’s how the collaboration came to be. We’re neighbors in the lab, and we were talking about this, and I was like, ‘Hey, I’ve got this piece of equipment. Let’s see how big these seeds are and if we can track them over time, using the same tools we use in polymer science.’”

The tool was vibrant light scattering, an essential strategy in Marciel’s group. It exposed that options reached a balance state under particular conditions, enabling a part of some seeds to stay undissolved in option.

The research study revealed those littles seed maintained the “memory” of the completely consistent slow-grown crystal from which they were ground, and Samani and Marciel discovered they might track the nucleation procedure that would ultimately permit the seeds to produce uniform thin movies.

Mohite stated the cooperation produced something that is frequently tried and hardly ever attained in nanomaterials research study — a self-assembly technique to make macroscopic products that measure up to the guarantee of the private nanoparticles of which they are made up.

“This is really the bane of nanomaterials technology,” Mohite stated. “At a specific, single aspect level, you have terrific residential or commercial properties that are orders of magnitude much better than anything else, however when you attempt to put them together into something macroscopic and beneficial, like a movie, those residential or commercial properties simply sort of disappear due to the fact that you cannot make something uniform, with simply those residential or commercial properties that you desire.

“We haven’t yet done experiments on other systems, but the success with perovskites begs the question of whether this type of seeded approach might work in other systems as well,” he stated.

Reference: “Memory Seeds Enable High Structural Phase Purity in 2D Perovskite Films for High-Efficiency Devices” by Siraj Sidhik, Wenbin Li, Mohammad H. K. Samani, Hao Zhang, Yafei Wang, Justin Hoffman, Austin K. Fehr, Michael S. Wong, Claudine Katan, Jacky Even, Amanda B. Marciel, Mercouri G. Kanatzidis, Jean-Christophe Blancon, Aditya D. Mohite, 6 June 2021, Advanced Materials.

DOI: 10.1002/adma.202007176

The research study was supported by the Department of Energy’s (DOE) Office of Energy Efficiency and Renewable Energy, the Academic Institute of France and the Office of Naval Research (N00014-20-1-2725) and used DOE centers at Argonne National Laboratory and Brookhaven National Laboratory.