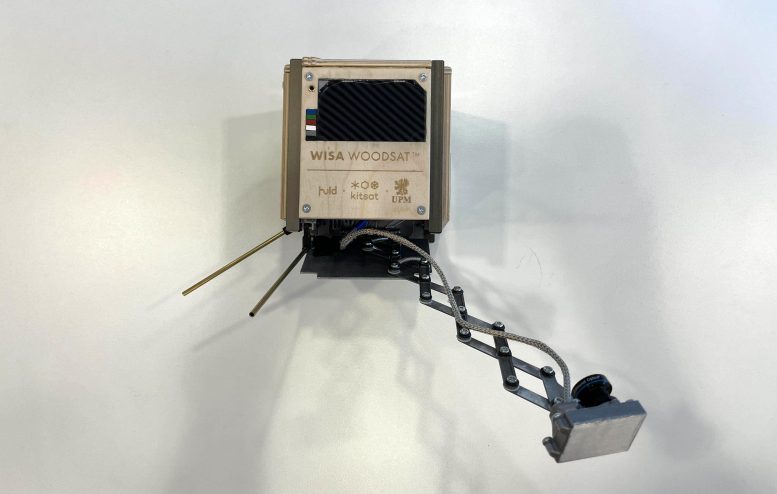

The world’s very first wood satellite is on the method, in the shape of the Finnish WISA Woodsat. ESA products specialists are contributing a suite of speculative sensing units to the objective along with assisting with pre-flight screening. Credit: Arctic Astronautics

The world’s very first wood satellite is on the method, in the shape of the Finnish WISA Woodsat. ESA products specialists are contributing a suite of speculative sensing units to the objective along with assisting with pre-flight screening.

WISA Woodsat is a 10x10x10 cm ‘CubeSat’ – a kind of nanosatellite developed from standardized boxes – however with surface area panels made from plywood. Woodsat’s just non-wooden external parts are corner aluminum rails utilized for its implementation into area plus a metal selfie stick.

The objective was started by Jari Makinen, Finnish author and broadcaster. He co-founded a business called Arctic Astronautics, which markets totally practical reproductions of orbit-ready CubeSats for education, training and pastime functions. “I’ve constantly delighted in making design airplanes, including a great deal of wood parts. Having operated in the area education field, this got me questioning; why don’t we fly any wood products in area?

WISA Woodsat. Credit: Arctic Astronautics

“So I had the idea first of all to fly a wooden satellite up to the stratosphere, aboard a weather balloon. That happened in 2017, with a wooden version of KitSat. That having gone well, we decided to upgrade it and actually go into orbit. From there the project just snowballed: we found commercial backing, and secured a berth on an Electron launcher from Rocket Lab in New Zealand.”

ESA sensing units to smell Woodsat’s interior

Riccardo Rampini, heading ESA’s Materials’ Physics and Chemistry area, remarks: “It’s been a tight schedule however we invited the chance to add to Woodsat’s payload in return for assisting evaluate its viability for flight.

“The very first product we’re embarking is a pressure sensing unit, which will permit us to determine the regional pressure in onboard cavities in the hours and days after launch into orbit. This is an essential element for the turn-on of high power systems and radio-frequency antennas, due to the fact that percentages of particles in the cavity can possibly trigger them damage.

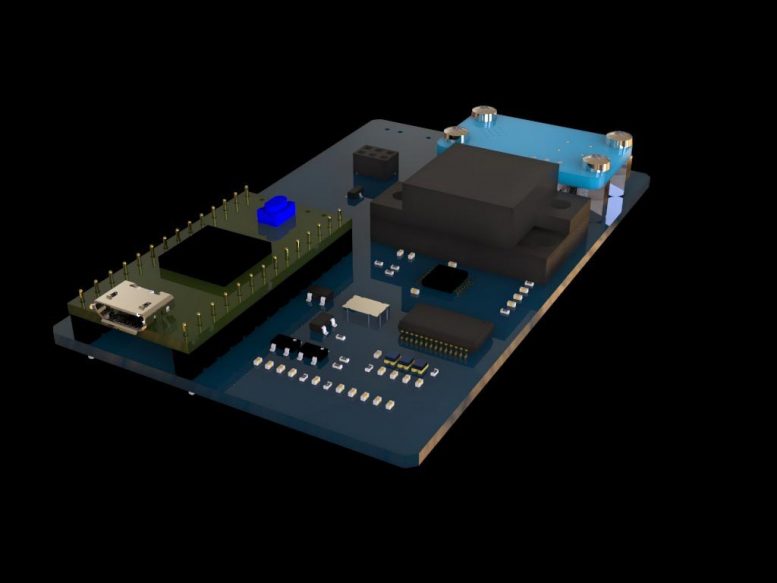

Revealing the WISA Woodsat style. Credit: Arctic Astronautics

“This sensor is being built for us by Sens4 in Denmark, who have done a great job to strip down their standard design to fit limited onboard volume and power constraints.”

ESA products engineer Bruno Bras includes: “The good thing here is we have ended up devising a low-cost device that could find all kinds of further uses, both in orbit and down on the ground in test environments.”

Next to it will be an uncomplicated LED with a photoresistor that senses as it illuminate. But the LED’s power will come through a 3D-printed electrically-conductive plastic called ‘polyether ether ketone’, or PEEK for brief, opening the possibility of printing power or even information links straight within the bodies of future area objectives.

ESA’s technical heart: ESTEC, the European Space Research and Technology Centre, in Noordwijk, the Netherlands. Credit: ESA-G. Porter

ESA products engineer Orcun Ergincan remarks: “The other item is a quartz crystal microbalance, serving as a highly sensitive contamination monitoring tool, measuring any faint deposits in the nanogram range coming from onboard electronics as well as the wooden surfaces themselves. This has been contributed by OpenQCM in Italy. This company is also building the overall printed circuit board stack hosting all three demonstrators with incorporated sensors.”

Plywood for Woodsat

Sponsors for Woodsat consist of UPM Plywood in Finland, amongst the biggest plywood makers worldwide.

“The base material for plywood is birch, and we’re using basically just the same as you’d find in a hardware store or to make furniture,” describes Woodsat primary engineer and Arctic Astronautics co-founder Samuli Nyman.

Made up of more than 20 devoted speculative centers and numerous instruments in general, ESA’s Materials & Electrical Components Laboratory ensures an ideal option of electrical elements, products and procedures for ESA objectives and external tasks, thinking about the special ecological difficulties associated with structure for area, in addition examining failures to make sure comparable concerns do not take place on future objectives. Credit: ESA

“The main difference is that ordinary plywood is too humid for space uses, so we place our wood in a thermal vacuum chamber to dry it out. Then we also perform atomic layer deposition, adding a very thin aluminum oxide layer – typically used to encapsulate electronics. This should minimize any unwanted vapors from the wood, known as ‘outgassing’ in the space field, while also protecting against the erosive effects of atomic oxygen. We’ll also be testing other varnishes and lacquers on some sections of the wood.”

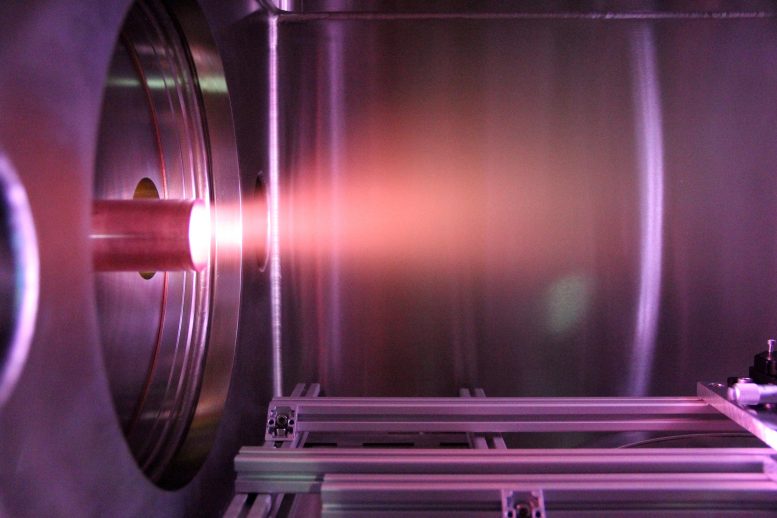

This extremely reactive oxygen variation is discovered at the fringes of the environment – the outcome of basic oxygen particles being disintegrated by effective ultraviolet radiation from the Sun – and was very first found when it gnawed thermal blankets on early Space Shuttle flights.

On Woodsat, ESA products engineers are embarking a pressure sensing unit, a test of electrically conductive plastic and a quartz crystal microbalance, all housed on the exact same printed circuit board, plus a test of shape memory alloy. Credit: ESA

Pre-flight screening recommends the satellite, which will orbit at around 500-600 km elevation in an approximately polar Sun-concurrent orbit, ought to endure its atomic oxygen direct exposure. But the wood is anticipated to be darkened by the ultraviolet radiation of unfiltered sunshine.

Onboard selfie stick

“We have a pair of onboard cameras, with one extended on a selfie stick to look back at the plywood and take pictures to see how it is behaving,” includes Jari. “We want to see color changes, any cracking and so on.”

Designing and production of the video camera boom showed an intriguing workout: the structure requires to be little as it can be within the small satellite for launch, then extend out as far as possible when in area.

ESA’s brand-new LEOX, Low Earth Orbit Facility, being fired for the very first time in April 2017. This brand-new simulator that fires a laser to create ‘atomic oxygen’ typically experienced just in low orbits – and understood to gnaw at satellite surface areas. LEOX creates atomic oxygen at energy levels that are comparable to orbital speed – 7.8 km/s – to replicate the area environment as carefully as possible. It can likewise evaluate at a greater circulation, conserving money and time for screening. Purified molecular oxygen is injected into a vacuum chamber with a pulsing laser beam focused onto it. With a purple flash each time the laser is fired, the oxygen is transformed into a hot plasma whose fast growth is funnelled along a cone-shaped nozzle. It then dissociates to form an extremely energetic beam of atomic oxygen. The brand-new center is housed in the Materials and Electrical Components Laboratory, among a suite of laboratories at ESA’s technical center in the Netherlands, dedicated to replicating every element of the area environment. Credit: ESA, CC BY-SA 3.0 IGO

“The design was made by Finnish engineering company Huld, pushing 3D printing to its limits,” includes Jari. “For Huld the Woodsat project has already proved an important reference point for entering other space mechanics projects, too.”

As well as the cams and ESA-donated sensing unit suite, Woodsat will likewise bring an amateur radio payload enabling beginners to relay radio signals and images around the world. To downlink information from this ‘LoRa’ radio link includes purchasing a ‘ground station’ costing just €10.

“In the end, Woodsat is simply a beautiful object in terms of traditional Nordic design and simplicity, it should be very interesting to see it in orbit,” continues Jari. “Our hope is it helps inspire people to take increased interest in satellites and the space sector as something that already touches all our lives, and is only going to get bigger in future.”

Woodsat is because of release prior to completion of this year.