HP boasts that its Metal Jet 3D printing innovation is much faster and for that reason more affordable than utilizing a laser to develop parts out of powdered metal.

HP.

Humans have actually found out great deals of methods to form metal– casting it with a mold, marking it, drilling holes and milling surface areas in a factory, even zapping it with a laser. Well, now you can include a brand-new technique: 3D printing.

A variety of business use metal 3D printing, which produces items and parts layer by layer with a computer-controlled system tracing its family tree to normal inkjet printers. But on Monday, printing huge HP revealed it’s gone into the marketplace with the aspiration to drastically lower rates, thanks to a $400,000 item called the Metal Jet.

“We’re really going to enable mass production for mainstream metals, in particular steels,” stated Tim Weber, head of 3D metal printing for HP.

HP has actually signed handle knowledgeable metal making partners and with consumers consisting of Volkswagen and Johnson & & Johnson MedicalDevices So do not be amazed if your next vehicle’s equipments or suspension links are constructed partially from this brand-new technique of digital fabrication.

Consulting company McKinsey sees an intense future for the innovation. “3D printing is a very small part of the metals industry, but it is growing rapidly and this market is expected to be worth as much as $10 billion by 2030 to 2035,” it stated in a 2017 report. “We expect the current low-scale experiments to shift to broader industrial adoption within the next five to 10 years.”

3D printing lets makers make little, comprehensive parts like this part of a medical instrument.

Array/ HP.

Why utilize 3D metal printing?

3D printing, likewise called additive production, lets you develop parts that are pricey or difficult to make with traditional production techniques. For example, you can make a part lighter with an interior lattice that’s strong however mainly hollow.

Although 3D printing is significantly typical today, it’s not the very first technique you ‘d utilize for making mainstream items. It’s frequently utilized to produce models, and although you can make 3D-printed plastic weapons, 3D-printed metal items and parts are a relative rarity.

Science fiction authors are delighted by the possibilities of 3D printing. Emma Newman’s Planetfall, Kim Stanley Robinson’s Aurora and Neal Stephenson’s The Diamond Age display makers that can produce whatever from spacecraft parts to internal organs. We’re no place near that future, however 3D metal printing is an action in that instructions, and there’s more coming.

For example, 3D printing might let you exactly engineer items utilizing numerous products– state, utilizing extremely long lasting metal on an equipment tooth however something more versatile in the equipment interior to make it quieter. “We’ve already done things like that in the lab,” Weber stated.

3D printing likewise can be much faster, minimize metal waste, integrate numerous parts that otherwise would need to be put together later on, and make it possible for “mass customization”– massive production of fine-tuned parts.

Each HP Metal Jet 3D printer is a substantial cabinet-sized device that’ll cost a bit under $400,000

HP.

How HP’s 3D metal printing works

HP’s Metal Jet today does not produce an ended up item, however.

It begins with a thin layer of powdered metal set on a bed. Then a line of print heads passes through the layer, spraying small drops of a binding representative– glue, basically– where strong metal is required.When one layer is done, a brand-new layer of powder is set followed by another pass for the binding representative. It takes about 4 or 5 hours to develop an item or group of items utilizing the printer’s complete volume of 430 x320 x200 millimeters, which has to do with 17 x13 x8 inches.

The printer operates at extremely high resolution. Its tiniest metal component– a voxel– procedures simply 20 x20 x50 microns, or millionths of a meter. For contrast, human hairs vary from about 17 to 181 microns in size.

When it’s done printing, the parts are secured and the unused powder is separated for reuse. The parts then go through a heating operation called sintering that merges the powder into a strong block. Sintering innovation is years old however complicated, which is why HP has actually signed collaborations for this phase with 2 production professionals, Parmatech and GKN Powder Metallurgy.

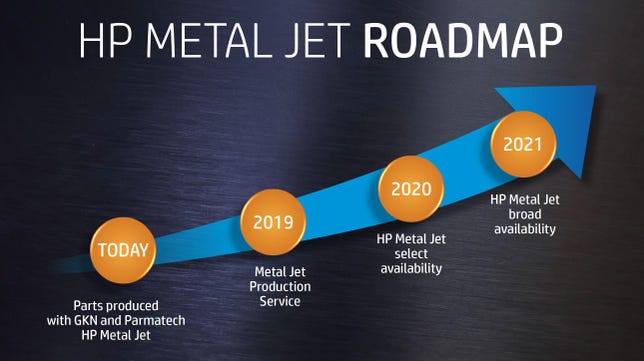

HP anticipates its Metal Jet 3D printing items to develop and end up being more traditional in coming years. For 2018, consumers will need to go through licensed printing services.

HP.

You’re still refrained from doing, though. Sintering decreases the size of the part by about 15 percent, Weber stated, and secondary processing places on the completing touches.

Why is this any much better than 3D printing from competitors like Markforged, Xometry or 3D Systems? Weber guarantees faster print times given that HP’s PageWide innovation moves band of print heads throughout the whole bed in one swipe per layer rather of sending out one print head passing through backward and forward again and again. And HP guarantees lower expenses due to the fact that it establishes and makes its own parts, most especially the print heads that should dependably spray the binding representative.

“We have 30-plus years of figuring out how to jet crazy stuff,” Weber stated.

The Smartest Stuff: Innovators are believing up brand-new methods to make you, and the important things around you, smarter.

Special Reports: CNET’s thorough functions in one location.