By

Innovative high-entropy alloys, crafted through laser-based additive production, deal extraordinary strength and ductility for commercial applications. These brand-new products, examined with sophisticated methods, guarantee improved efficiency in severe conditions. Credit: SciTechDaily.com

Laser- based additive production produces high-entropy alloys that are more powerful and less most likely to fracture.

Researchers make a kind of product called resilient high-entropy alloys (HEAs) by integrating numerous essential metals. HEAs have prospective usages in applications including serious wear and tear, severe temperature levels, radiation, and high tension.

They can be used 3D printing, likewise called additive production (AM), however this normally leads to bad ductility. This suggests 3D-printed HEAs are tough to form and do not warp, or stretch, enough under loads to avoid fractures.

Scientists have actually now utilized laser-based AM to form HEAs that are more powerful and a lot more ductile. They utilized neutron and X-ray scattering and electron microscopy to much better comprehend the systems of these efficiency enhancements.

Potential Industrial Applications and Energy Efficiency

Industry might one day usage more powerful and more quickly shaped HEAs in production. To operate in these applications, light and intricate HEA parts require enhanced sturdiness, dependability, and resistance to fracturing.

This would benefit customers and market, for instance, by allowing the production of much safer and more fuel-efficient lorries, more powerful items, and longer-lasting equipment. In addition, laser-based AM, in which lasers fuse powdered alloys into strong metal shapes, is extremely energy effective. This makes it appealing for producing brand-new kinds of HEAs.

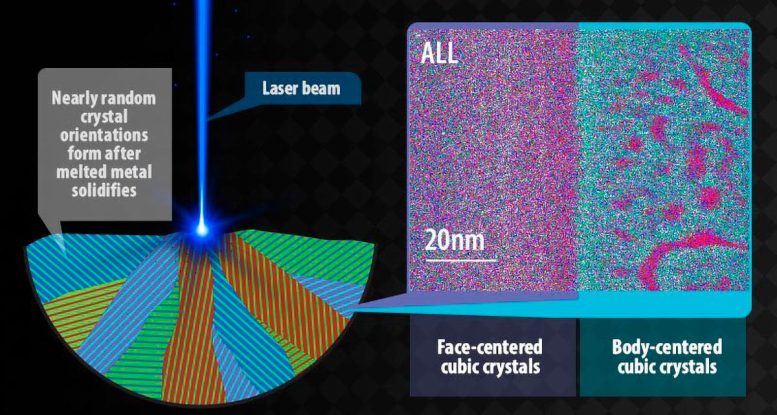

Images of the 2 crystal structures (right) discovered in a high-entropy alloy (left) made by additive production. Credit: University of Massachusetts Amherst

Nano-Lamellae Structure and Mechanical Properties

The laser-based AM procedure produced nanometer-thick nano-lamellae (thin layers of plates) using high strength, while the plates’ unique edges allow a degree of slippage (ductility). The plates include rotating layers of face-centered cubic (FCC) crystal structures that balance roughly 150 nanometers thick and body-centered cubic (BCC) crystal structures that balance roughly 65 nanometers thick.

The brand-new HEAs showed high yield strengths of about 1.3 gigapascals– surpassing the greatest titanium alloys. These HEAs likewise use an elongation of about 14%, which is greater than other AM metal alloys offered the exact same yield strength. Elongation is a step of just how much flexing a product can endure without breaking.

Advanced Research Techniques and Facilities

Neutron information from the Spallation Neutron Source, a Department of Energy (DOE) Office of Science user center at Oak Ridge National Laboratory (ORNL), made it possible for the scientists to analyze the interior mechanical load sharing of the HEA samples while under stress.

The scientists utilized an < period class ="glossaryLink" aria-describedby ="tt" data-cmtooltip ="<div class=glossaryItemTitle>atom</div><div class=glossaryItemBody>An atom is the smallest component of an element. It is made up of protons and neutrons within the nucleus, and electrons circling the nucleus.</div>" data-gt-translate-attributes="[{"attribute":"data-cmtooltip", "format":"html"}]" tabindex ="0" function ="link" > atom probe instrument at theCenter forNanophaseMaterials(*************************************************************************************************************** )likewise a DOE user center at ORNL, to catch comprehensive 3D pictures of the structures and microstructures, including rotating nano-lamellae layers. (************ )

The stages of various annealed samples were studied utilizing X-ray diffraction at theAdvancedPhotonSource, another DOEOffice ofScience user center atArgonneNationalLaboratory

Reference:“Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing” byJieRen,YinZhang,DexinZhao,YanChen,ShuaiGuan,YanfangLiu,LiangLiu,SiyuanPeng,FanyueKong,Jonathan D.Poplawsky,GuanhuiGao,ThomasVoisin,KeAn, Y.MorrisWang,Kelvin Y.Xie,TingZhu andWenChen, 3August2022,Nature

DOI:101038/ s41586-022-04914 -8

This research study was carried out at the Spallation Neutron Source, the Advanced Photon Source, and Center for Nanophase Materials Sciences, all of which are DOE Office of Science user centers. Funding assistance for this work consisted of the National Science Foundation, the University of Massachusetts Amherst, and the Laboratory Directed Research and Development program at Lawrence Livermore National Laboratory.