Accurate positioning of quantum dots with photonic elements is crucial for drawing out the radiation discharged by the dots. In this illustration, a quantum dot focused in the optical “hotspot” of a circular grating (center dot in the inset) gives off more light than a dot that is misaligned (off-center dot in the inset). Credit: S. Kelley/ NIST

Traceable microscopy might enhance the dependability of quantum infotech, biological imaging, and more.

Devices that catch the fantastic light from countless quantum dots, consisting of chip-scale lasers and optical amplifiers, have actually made the shift from lab experiments to business items. But more recent kinds of quantum-dot gadgets have actually been slower to come to market since they need extremely precise positioning in between specific dots and the mini optics that draw out and direct the discharged radiation.

Breakthrough in Quantum Dot Alignment

Researchers at the National Institute of Standards and Technology (NIST) and their coworkers have actually now established requirements and calibrations for optical microscopic lens that enable quantum dots to be lined up with the center of a photonic part to within a mistake of 10 to 20 nanometers (about one-thousandth the density of a sheet of paper). Such positioning is crucial for chip-scale gadgets that use the radiation discharged by quantum dots to shop and transfer quantum info.

Enhancing Quantum Device Performance

For the very first time, the NIST scientists attained this level of < period class ="glossaryLink" aria-describedby ="tt" data-cmtooltip ="<div class=glossaryItemTitle>accuracy</div><div class=glossaryItemBody>How close the measured value conforms to the correct value.</div>" data-gt-translate-attributes="(** )" tabindex ="0" function ="link" > precision throughout the whole image from an optical microscopic lense, allowing them to remedy the positions of numerous specific quantum dots. A design established by the scientists anticipates that if microscopic lens are adjusted utilizing the brand-new requirements, then the variety of high-performance gadgets might increase by as much as a hundred-fold.

(************ )That brand-new capability might allow quantum infotech that are gradually emerging from lab to be more dependably studied and effectively turned into business items.

CalibrationChallenges andSolutions

In establishing their approach, Craig Copeland,Samuel Stavis, and their partners, consisting of coworkers from the JointQuantum Institute (JQI), a research study collaboration in between NIST and theUniversity ofMaryland, produced requirements and calibrations that were traceable to the InternationalSystem ofUnits (SI) for optical microscopic lens utilized to direct the positioning of quantum dots.

“The seemingly simple idea of finding a quantum dot and placing a photonic component on it turns out to be a tricky measurement problem,”Copeland stated.

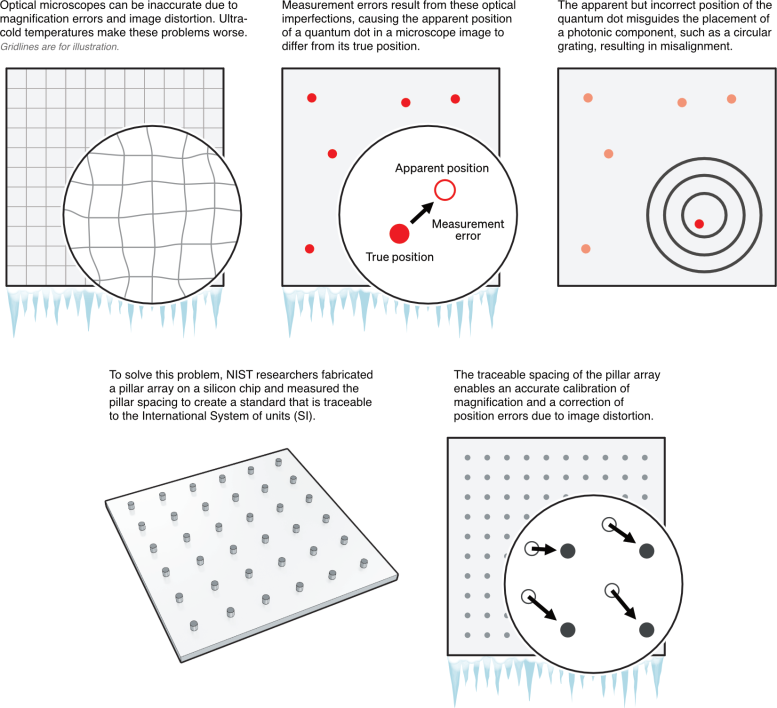

Addressing Microscopic MeasurementErrors

(*********************************************************************************************************************************** )a normal measurement, mistakes start to collect as scientists utilize an optical microscopic lense to discover the area of specific quantum dots, which live at random areas on the surface area of a semiconductor product.If scientists neglect the shrinking of semiconductor products at the ultracold temperature levels at which quantum dots run, the mistakes grow bigger.(******************************************************************************************************************************************** )making complex matters, these measurement mistakes are intensified by errors in the fabrication procedure that scientists utilize to make their calibration requirements, which likewise impacts the positioning of the photonic elements.

NIST’s Methodological Innovations

The NIST approach, which the scientists explained in a short article published online in Optica Quantum on March 18, recognizes and remedies such mistakes, which were formerly ignored.

Illustration demonstrating how traceable calibration of an optical microscopic lense can remedy for instrument flaws that would otherwise lead to misalignment of quantum dots with photonic elements. Credit: S. Kelley/ NIST

The NIST group produced 2 kinds of traceable requirements to adjust optical microscopic lens– initially at space temperature level to evaluate the fabrication procedure, and after that at cryogenic temperature levels to determine the area of quantum dots. Building on their previous work, the room-temperature basic included a range of < period class ="glossaryLink" aria-describedby ="tt" data-cmtooltip ="<div class=glossaryItemTitle>nanoscale</div><div class=glossaryItemBody>The nanoscale refers to a length scale that is extremely small, typically on the order of nanometers (nm), which is one billionth of a meter. At this scale, materials and systems exhibit unique properties and behaviors that are different from those observed at larger length scales. The prefix "nano-" is derived from the Greek word "nanos," which means "dwarf" or "very small." Nanoscale phenomena are relevant to many fields, including materials science, chemistry, biology, and physics.</div>" data-gt-translate-attributes="[{"attribute":"data-cmtooltip", "format":"html"}]" tabindex ="0" function ="link" > nanoscale holes spaced a set range apart in a metal movie.(********** )(************ )The scientists then determined the real positions of the holes with an atomic force microscopic lense, making sure that the positions were traceable to the SI.By comparing the evident positions of the holes as seen by the optical microscopic lense with the real positions, the scientists evaluated mistakes from zoom calibration and image distortion of the optical microscopic lense.The adjusted optical microscopic lense might then be utilized to quickly determine other requirements that the scientists made, making it possible for an analytical analysis of the precision and irregularity of the procedure.

“Good statistics are essential to every link in a traceability chain,” stated NIST scientistAdamPintar, a co-author of the short article.

Extending their approach to low temperature levels, the research study group adjusted an ultracold optical microscopic lense for imaging quantum dots.To perform this calibration, the group produced a brand-new microscopy requirement– a range of pillars made on a silicon wafer. The researchers dealt with silicon since the shrinking of the product at low temperature levels has actually been precisely determined.

Overcoming Optical Distortions at Low Temperatures

The scientists found a number of risks in adjusting the zoom of cryogenic optical microscopic lens, which tend to have even worse image distortion than microscopic lens running at space temperature level. These optical flaws flex the images of straight lines into knotted curves that the calibration efficiently corrects. If uncorrected, the image distortion triggers big mistakes in identifying the position of quantum dots and in lining up the dots within targets, waveguides, or other light-controlling gadgets.

“These errors have likely prevented researchers from fabricating devices that perform as predicted,” stated NIST scientist Marcelo Davanco, a co-author of the short article.

Quantum Dot Device Improvement and Future Applications

The scientists established a comprehensive design of the measurement and fabrication mistakes in incorporating quantum dots with chip-scale photonic elements. They studied how these mistakes restrict the capability of quantum-dot gadgets to carry out as created, discovering the capacity for a hundred-fold enhancement.

“A researcher might be happy if one out of a hundred devices works for their first experiment, but a manufacturer might need ninety-nine out of a hundred devices to work,” Stavis kept in mind. “Our work is a leap ahead in this lab-to-fab transition.”

Beyond quantum-dot gadgets, traceable requirements and calibrations under advancement at NIST might enhance precision and dependability in other requiring applications of optical microscopy, such as imaging brain cells and mapping neural connections. For these ventures, scientists likewise look for to identify precise positions of the items under research study throughout a whole microscopic lense image. In addition, researchers might require to collaborate position information from various instruments at various temperature levels, as holds true for quantum-dot gadgets.

Reference: “Traceable localization enables accurate integration of quantum emitters and photonic structures with high yield” by Daron A. Westly, Ronald G. Dixson, B. Robert Ilic, Marcelo I. Davanco, Samuel M. Stavis, Craig R. Copeland, Ashish Chanana, Kartik Srinivasan and Adam L. Pintar, 24 April 2024, Optica Quantum

DOI: doi: 10.1364/ OPTICAQ.502464