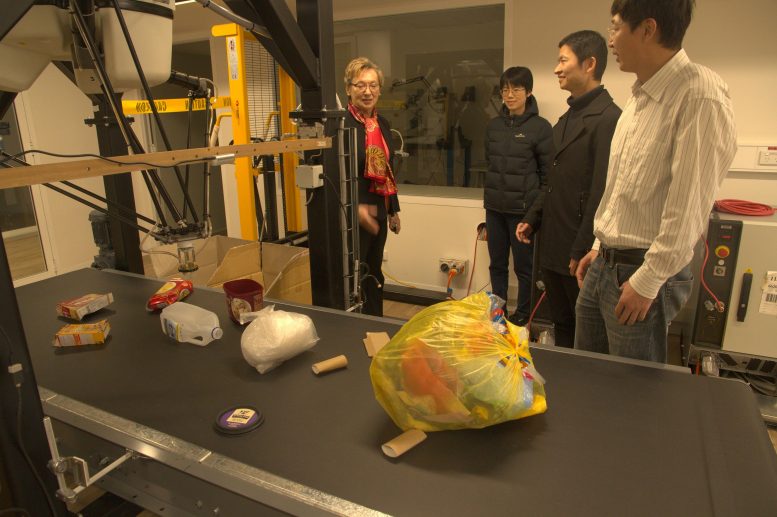

University of Sydney scientists develop a robotic that sorts soft plastics. Credit: University of Sydney

- Researchers develop robotic that sorts soft plastic

- Technology might be an advantage for recycling market

Engineering scientists are establishing a unique approach to increase the recycling of soft plastics by producing a clever robotic that can recognize, sort and separate various kinds of recyclable waste.

Despite an enhancement in plastic recycling in the last few years, garbage dump is a growing concern. Soft plastics like stick wrap and plastic bags are a significant factor to the issue, with 94 percent going to garbage dump in 2016-17.

Soft plastics do not have sufficient recycling techniques as they quickly entangle in waste separation equipment, resulting in mechanical failure and contamination of other recyclable products such as paper. Because of this issue, existing recycling techniques count on the manual sorting of soft plastics, a frequently recurring and hazardous job.

Working along with market partners as part of a federal government Cooperative Research Centre Project grant, scientists from the Centre for Internet of Things (IoT) and Telecommunications at the University of Sydney are establishing a unique approach to increase recycling of soft plastics – by producing a clever, automatic robotic system that utilizes an AI to arrange recyclable waste.

The group consists of Professor Branka Vucetic, Professor Yonghui Li, Associate Professor Wanli Ouyang, Dr. Wanchun Liu, and Senior Technical Officer Dawei Tan from the School of Electrical and Information Engineering.

Professor Branka Vucetic, Dr. Wanchun Liu, Dr. Wanli Ouyang, Professor Yonghui Li with their recycling robotic. Credit: University of Sydney

“The recycling robotic automation system will use artificial intelligence and computer vision to learn how to identify different forms of recycling waste, effectively learning how to ‘see’ and ‘sort’ waste, to create separate waste streams and maintain soft plastics’ purity so they can be recycled,” stated IoT specialist, Professor Branka Vucetic.

“Soft plastics are a big contributor to landfills and have long been a challenge for the circular economy and waste management sector, as they have lacked an adequate and safe sorting method. Using the latest IoT techniques, we have created a custom robot to solve this issue,” stated Professor Yonghui Li.

“Between 2018 and 2019, Australia generated 2.5 million tonnes of plastic waste, which included soft plastics: only 9 percent was sent to recycling while 84 percent went to landfill. We aim to drastically switch those percentages by developing a solution that allows for most soft plastic waste being recycled,” stated Dr. Wanchun Liu.

The scientists are dealing with waste management business, IQRenew and CurbCycle, innovation designers Licella, Mike Ritchie and Associates, and Resource Recovery Design to establish the system.

“Soft plastics are a big contributor to landfill and have long been a challenge for the circular economy and waste management sector, as they have lacked an adequate and safe sorting method.”

— Professor Yonghui Li, School of Electrical and Information Engineering

The system will be incorporated into IQ Renew’s product healing center as part of CurbCycle’s soft plastic healing program, an Australian effort that includes the home collection of recyclables that are segregated into bags prior to positioning them into their kerbside recycling bin.

“Not only does our project divert household soft plastics from going to landfill; by creating a solution for the collection and sorting of waste with our industry and research partners, we’re also creating a sustainable supply chain that takes rubbish from households to end markets,” stated Associate Professor Wanli Ouyang.

“The robot will identify ‘CurbyTagged’ bags and differentiate sources of plastic, separating soft plastics from the fully co-mingled recyclables,” he stated.

After being separated from other waste, the soft plastics will be utilized for numerous functions, consisting of innovative recycling into oils and other important chemicals utilizing trademarked Catalytic Hydrothermal Reactor innovation (Cat-HTR™) produced by Licella Holdings. Licella was established by Professor Thomas Maschmeyer from the Faculty of Science along with Licella CEO, Dr. Len Humphreys, and has actually been supported by the University of Sydney for 14 years.

“This highly innovative materials handling process can help extend the range of the Cat-HTR conversion technology to now include increasingly challenging waste streams, highlighting the benefit of close industrial and academic collaboration,” stated Professor Maschmeyer.

The scientists were granted $2,999,220 as part of an Australian Federal Government CRC-P grant.

Professor Thomas Maschmeyer from the University’s School of Chemistry holds the position of Principal Technology Consultant at Licella.