Mineralization of 3D lattice formed by DNA tetrahedra (about 30 nm) and gold nanoparticle into all-inorganic 3D silica-Au replicas with maintained architecture. Credit: Oleg Gang/Columbia Engineering

Columbia Engineers usage DNA nanotechnology to develop extremely durable artificial nanoparticle-based products that can be processed through traditional nanofabrication techniques.

Columbia Engineering scientists, dealing with Brookhaven National Laboratory, report today that they have actually developed created nanoparticle-based 3D products that can endure a vacuum, heats, high pressure, and high radiation. This brand-new fabrication procedure leads to robust and completely crafted nanoscale structures that not just can accommodate a range of practical nanoparticle types however likewise can be rapidly processed with traditional nanofabrication techniques.

“These self-assembled nanoparticles-based materials are so resilient that they could fly in space,” states Oleg Gang, teacher of

Movie envisions a 3D restoration (utilizing FIB-SEM) of silicated DNA-nanoparticle lattice. The restoration reveals gold nanoparticles in lattice (silica structure is not noticeable). The lattice turns about the axis to picture the structure from numerous instructions. Credit: Oleg Gang/Columbia Engineering

Material residential or commercial properties are various at the nanoscale and scientists have actually long been checking out how to utilize these small products — 1,000 to 10,000 times smaller sized than the density of a human hair — in all type of applications, from making sensing units for phones to developing much faster chips for laptop computers. Fabrication methods, nevertheless, have actually been challenging in recognizing 3D nano-architectures. DNA nanotechnology makes it possible for the development of complexly arranged products from nanoparticles through self-assembly, however offered the soft and environment-dependent nature of DNA, such products may be steady under just a narrow series of conditions. In contrast, the freshly formed products can now be utilized in a broad series of applications where these crafted structures are needed. While traditional nanofabrication masters producing planar structures, Gang’s brand-new technique enables fabrication of 3D nanomaterials that are ending up being important to many electronic, optical, and energy applications.

Gang, who holds a joint consultation as group leader of the Soft and Bio Nanomaterials Group at Brookhaven Lab’s Center for Functional Nanomaterials, is at the leading edge of DNA nanotechnology, which counts on folding DNA chain into wanted 2 and three-dimensional nanostructures. These nanostructures end up being foundation that can be configured by means of Watson-Crick interactions to self-assemble into 3D architectures. His group styles and types these DNA nanostructures, incorporates them with nanoparticles and directs the assembly of targeted nanoparticle-based products. And, now, with this brand-new strategy, the group can shift these products from being soft and delicate to strong and robust.

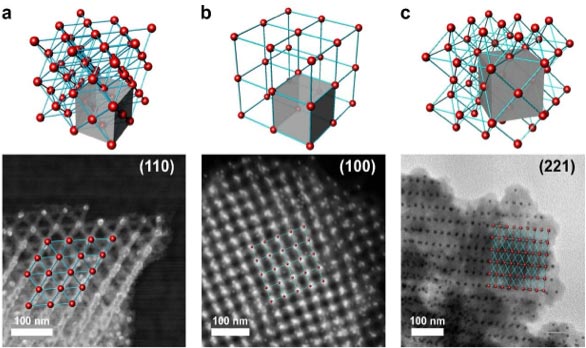

Different kinds of nanoscale lattices formed with polyhedra DNA nano-frames (tetrahedra, cubes, and octahedra) and gold nanoparticle are mineralized with manageable silica finish densities (from about 5nm to a complete space-filling). Credit: Oleg Gang/Columbia Engineering

This brand-new research study shows an effective technique for transforming 3D DNA-nanoparticle lattices into silica reproductions, while preserving the geography of the interparticle connections by DNA struts and the stability of the nanoparticle company. Silica works well due to the fact that it assists keep the nanostructure of the moms and dad DNA lattice, forms a robust cast of the underlying DNA and does not impact nanoparticles plans.

“The DNA in such lattices takes on the properties of silica,” states Aaron Michelson, a PhD trainee from Gang’s group. “It becomes stable in air and can be dried and allows for 3D nanoscale analysis of the material for the first time in real space. Moreover, silica provides strength and chemical stability, it’s low-cost and can be modified as needed — it’s a very convenient material.”

To discover more about the residential or commercial properties of their nanostructures, the group exposed the transformed to silica DNA-nanoparticles lattices to severe conditions: heats above 1,0000C and high mechanical tensions over 8GPa (about 80,000 times more than environment pressure, or 80 times more than at the inmost ocean location, the Mariana trench), and studied these procedures in-situ. To evaluate the structures’ practicality for applications and more processing actions, the scientists likewise exposed them to high dosages of radiation and focused ion beams.

“Our analysis of the applicability of these structures to couple with traditional nanofabrication techniques demonstrates a truly robust platform for generating resilient nanomaterials via DNA-based approaches for discovering their novel properties,” Gang notes. “This is a big step forward, as these specific properties mean that we can use our 3D nanomaterial assembly and still access the full range of conventional materials processing steps. This integration of novel and conventional nanofabrication methods is needed to achieve advances in mechanics, electronics, plasmonics, photonics, superconductivity, and energy materials.”

Collaborations based upon Gang’s work have actually currently resulted in unique superconductivity and conversion of the silica to conductive and semiconductive media for more processing. These consist of an earlier research study released by Nature Communications and one just recently released by Nano Letters. The scientists are likewise preparing to customize the structure to make a broad series of products with extremely preferable mechanical and optical residential or commercial properties.

“Computers have been made with silicon for over 40 years,” Gang includes. “It took four decades to push the fabrication down to about 10 nm for planar structures and devices. Now we can make and assemble nanoobjects in a test tube in a couple of hours without expensive tools. Eight billion connections on a single lattice can now be orchestrated to self-assemble through nanoscale processes that we can engineer. Each connection could be a transistor, a sensor, or an optical emitter — each can be a bit of data stored. While Moore’s law is slowing, the programmability of DNA assembly approaches is there to carry us forward for solving problems in novel materials and nanomanufacturing. While this has been extremely challenging for current methods, it is enormously important for emerging technologies.”

The research study is entitled “Resilient Three-Dimensional Ordered Architectures Assembled from Nanoparticles by DNA.”

Authors are: Pawel W. Majewski 1,2, Aaron Michelson3, Marco A. L. Cordeiro1, Cheng Tian1, Chunli Ma1, Kim Kisslinger1, Ye Tian1, Wenyan Liu1, Eric A. Stach3, Kevin G. Yager1, Oleg Gang1, 3, 5

1Center for Functional Nanomaterials, Brookhaven National Laboratory

2Department of Chemistry, University of Warsaw, Poland

3Department of Applied Physics and Applied Mathematics, Columbia University

4Department of Materials Science and Engineering, University of Pennsylvania

5Department of Chemical Engineering, Columbia University

DOI: 10.1126/sciadv.abf0617

The research study was supported by United States Department of Defense, Army Research Office, W911NF-19-1-0395. This research study utilized resources of the Center for Functional Nanomaterials and the National Synchrotron Light Source II, which are U.S. DOE Office of Science Facilities, at Brookhaven National Laboratory under Contract No. DE-SC0012704. The DNA style work was supported by the United States Department of Energy, Office of Basic Energy Sciences, Grant DE-SC0008772.