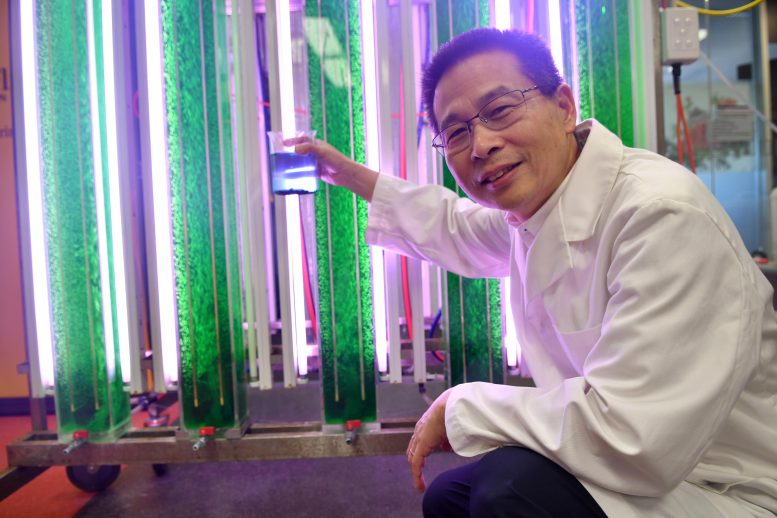

Industrial scale micro-algal bioreactors. Credit: Stock images

Marine microalgae-based cellular farming is an appealing brand-new method to sustainably produce plant-based ‘meat’ and healthy ‘superfoods’ for the future.

Researchers at Flinders University’s Centre for Marine Bioproducts Development (CMBD) in Australia are reacting to growing interest from customers searching for much healthier, more eco-friendly, sustainable and ethical options to animal proteins.

Marine microalgae, single-cell photosynthetic organisms from the ocean might be the option to the world’s meat protein lack, states CMBD director Flinders University Professor Wei Zhang, who is likewise co-leading a quote to develop a nationwide Marine Bioproducts Cooperative Research Centre (MB-CRC) in Australia.

The CRC’s objective is to discover methods to establish the third-generation of Australian high-value marine bioindustry (rather than the first-generation of fisheries and the second-generation of aquaculture) and change Australia’s emerging marine bioproducts sector into a worldwide competitive market.

The Centre’s focus will be on market and market-driven developments to enhance both the supply chain and worth chain to provide expenses cost savings, enhanced production and competitive capability for Australia to gain access to high worth marine bioproducts markets around the world.

The Flinders University Centre for Marine Bioproducts Development bioreactor and processed microalgae sample held by Professor Wei Zhang, who is co-leading a quote to develop a nationwide Marine Bioproducts Cooperative Research Centre (MB-CRC) in Australia. Credit: Flinders University

“Our research spans the entire value chain, from microalgae cultivation and circular advanced biomanufacturing to the development of high-value functional food,” Professor Zhang states.

“Microalgae come in a diverse range of nutritional profiles and advanced cultivation strategies can be developed for tuning microalgae to produce protein-, oil- and carbohydrate-dominant types that can be processed into a broad range of functional foods, including healthy cell patties, chips, pastes, jams and even caviar.”

Two freshwater microalgal items presently on the marketplace are the high protein Chlorella and Spirulina ranges utilized in the production of foods such as green pasta, beverages and drinks.

Marine types are of substantial interest as they do not need limited freshwater and crop land. Their special dietary profiles such as their high DHA and EPA material (long chain omega 3 fats) are vital for baby and brain advancement and heart health.

Bioreactors for upscaling upscaled marine production of photosynthetic microalgae can likewise assist to fight greenhouse gas emissions and environment modification. One 90 x 90 x 210 cm (3 x 3 x 7 feet) bioreactor system can take in as much as 400 times more co2 than the very same footprint of trees.

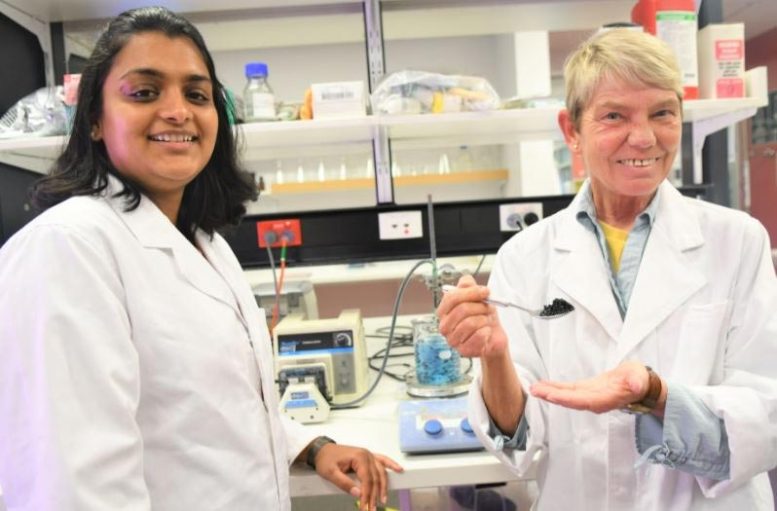

Centre for Marine Bioproducts Development scientists Dr Reinu Abraham and Associate Professor Kirsten Heimann with ‘caviar’ made from microalgae at the Flinders University lab. Credit: Flinders University

Using sunshine, particular ranges of microalgae produce oxygen and transform co2 into natural carbon (protein, carbs, pigments, fats, and fibers), similar to plants, however do not need important arable land for their production.

“They are therefore often called the rainforests of the oceans,” states Associate Professor Kirsten Heimann, senior speaker in biotechnology at Flinders University.

“Using sunshine, photosynthetic microalgae produce oxygen and transform co2 into natural carbon (protein, carbs, pigments, fats, fibers, and micronutrients), similar to plants, however do not need important arable land for their production.

This indicates microalgae can be sustainably gathered and transformed into environmentally friendly superfoods,” she states. “Putting one and one together, microalgae and innovative production and processing could help to service the world’s booming population and growing demand for sustainable protein production,” she states.

Along with research study into processing methods, the CMBD group is likewise examining making use of waste or gathered seaweed for eco-friendly plastics production, another sustainable option to non-degradable petroleum-based plastics.

Reference: “Release of encapsulated bioactives influenced by alginate viscosity under in-vitro gastrointestinal model” by Reinu E. Abraham, Peng Su, Munish Puri, Colin L. Raston and Wei Zhang, 4 January 2021, International Journal of Biological Macromolecules.

DOI: 10.1016/j.ijbiomac.2020.12.143

The results show making use of both microalgae and macroalgae for advancement of regulated release of health and dietary bioactives from marine sources.