Prototype of the solar batteries in lab size (TPC – Transparent Passivating Contact). Four solar batteries, each determining 4 square centimeters, can be seen on the silicon wafer, each of which is called and framed with screen-printed silver contacts. Credit: Forschungszentrum Jülich

Nanostructured product and a brand-new cell style lead the way for the production of silicon solar batteries with more than 26 percent effectiveness.

There is no less expensive method to produce electrical energy today than with the sun. Power plants are presently being integrated in warm areas that will provide solar electrical energy for less than 2 cents per kilowatt hour. Solar cells readily available on the marketplace based upon crystalline silicon make this possible with effectiveness of approximately 23 percent. Therefore they hold an international market share of around 95 percent. With even greater effectiveness of more than 26 percent, expenses might fall even more. An worldwide working group led by photovoltaics scientists from Forschungszentrum Jülich now prepare to reach this objective with a nanostructured, transparent product for the front of solar batteries and an advanced style. The researchers report on their success of several years of research study in the popular clinical journal Nature Energy.

Silicon solar batteries have actually been gradually enhanced over the previous years and have actually currently reached an extremely high level of advancement. However, the troubling impact of recombination still takes place after the absorption of sunshine and the photovoltaic generation of electrical charge providers. In this procedure, unfavorable and favorable charge providers that have actually currently been produced integrate and cancel each other out prior to they might be utilized for the circulation of solar electrical energy. This impact can be countered by unique products that have an unique home — passivation.

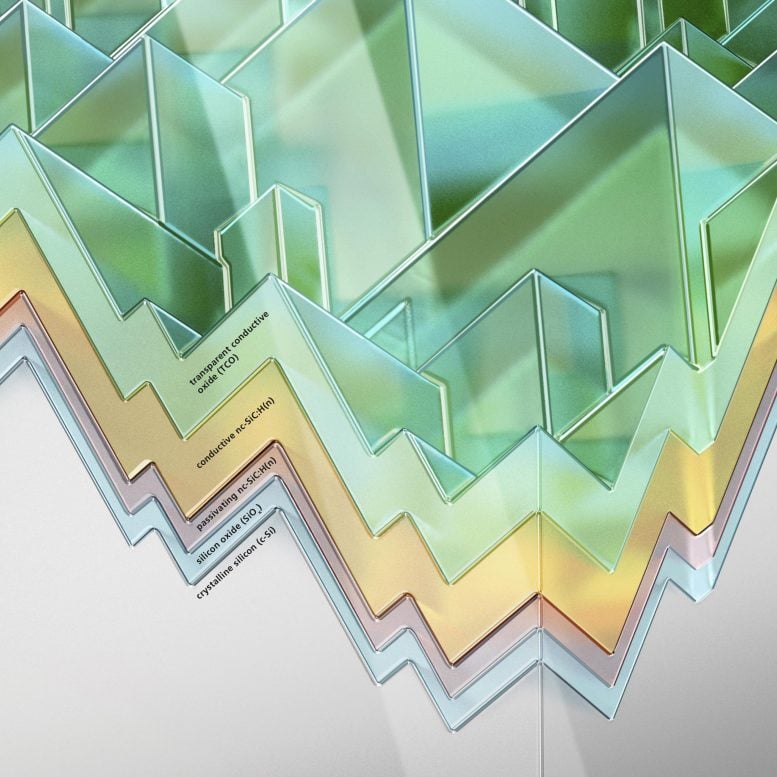

Layer series of the brand-new solar batteries with transparent frontal layers (TPC, Transparent Passivating Contact) on a wafer with random pyramid structure. The gray location represents the n-doped crystalline silicon wafer, the light blue layer is the wet-chemically grown silicon dioxide, the red layer represents the passivating silicon carbide, followed by the carrying out silicon carbide in orange. The green, last layer represents the indium tin oxide (ITO). Credit: Forschungszentrum Jülich

“Our nanostructured layers offer precisely this desired passivation,” states Malte Köhler, previous PhD trainee and very first author from the Jülich Institute for Energy and Climate Research (IEK-5), who has actually because gotten his doctorate. In addition, the ultra-thin layers are transparent — so the occurrence of light is barely minimized — and show high electrical conductivity.

“No other approach so far combines these three properties — passivation, transparency, conductivity — as well as our new design,” states Dr. Kaining Ding, head of the Jülich working group. A very first model of the Jülich TPC solar battery attained a high effectiveness of 23.99 percent (+- 0.29 percent) in the lab. This worth was likewise validated by the independent CalTeC lab of the Institute for Solar Energy Research in Hamelin (ISFH). This suggests that the Jülich TPC solar battery still ranks somewhat listed below the very best crystalline silicon cells made in labs to date. But simulations performed in parallel have actually revealed that effectiveness of more than 26 percent are possible with TPC innovation.

“In addition, we have only used processes in manufacturing that can be integrated relatively quickly into series production,” Ding highlights the benefit over other research study techniques. With this method, the Jülich researchers lead the way for their advancement from the lab to a big scale in commercial solar battery production without excessive effort.

Several procedure actions were needed to produce the layers of the TPC solar battery. On a thin layer of silicon dioxide, the scientists transferred a double layer of small pyramid-shaped nanocrystals of silicon carbide — used at 2 various temperature levels. Finally, a transparent layer of indium tin oxide followed. Ding and coworkers utilized damp chemical procedures, chemical vapor deposition (CVD) and a sputtering procedure.

For their success, the Jülich scientists from IEK 5 and of the Jülich Ernst Ruska Center for Electron Microscopy worked carefully together with a number of institutes in the Netherlands, China, Russia and Ecuador. The partners consist of scientists from RWTH Aachen University, the University of Duisburg-Essen, the Technical Universities of Delft and Eindhoven, the Universidad San Francisco de Quito, the University and Kutateladze Institute of Thermophysics in Novosibirsk and Sun Yat-Sen University in Guangzhou. In more actions, Kaining Ding’s research study group prepares to more enhance the power yield of its TPC solar batteries. “We expect solar cell manufacturers to show great interest in our technology,” Ding states.

Reference: “A silicon carbide-based highly transparent passivating contact for crystalline silicon solar cells approaching efficiencies of 24%” BY Malte Köhler, Manuel Pomaska, Paul Procel, Rudi Santbergen, Alexandr Zamchiy, Bart Macco, Andreas Lambertz, Weiyuan Duan, Pengfei Cao, Benjamin Klingebiel, Shenghao Li, Alexander Eberst, Martina Luysberg, Kaifu Qiu, Olindo Isabella, Friedhelm Finger, Thomas Kirchartz, Uwe Rau and Kaining Ding, 15 April 2021, Nature Energy.

DOI: 10.1038/s41560-021-00806-9