A replenishment oiler, left, refuels a marine ship at sea. The Porosoff research study group at the University of Rochester has actually shown that a potassium-promoted molybdenum carbide driver can assist the United States Navy accomplish its objective of transforming seawater to fuel, efficiently getting rid of the requirement for standard refueling operations. Credit: United States Navy

For the very first time, Rochester chemical engineers have actually shown a ‘potassium-promoted’ driver’s capacity for usage on a commercial scale.

Now, the Navy’s mission to power its ships by transforming seawater into fuel is nearer to fulfillment.

This reactor at OxEon Energy was utilized to verify the efficiency of the potassium-promoted molybdenum carbide driver on a commercial scale. Credit: OxEon Energy

University of Rochester chemical engineers—in partnership with scientists at the Naval Research Laboratory, the University of Pittsburgh, and OxEon Energy—have actually shown that a potassium-promoted molybdenum carbide driver effectively and dependably transforms co2 to carbon monoxide gas, an important action in turning seawater into fuel.

“This is the first demonstration that this type of molybdenum carbide catalyst can be used on an industrial scale,” states Marc Porosoff, assistant teacher in the Department of Chemical Engineering at Rochester. In a paper in the journal Energy & Environmental Science, the scientists explain an extensive series of experiments they carried out at molecular, lab, and pilot scales to record the driver’s viability for scale-up.

If navy ships might develop their own fuel from the seawater they take a trip through, they might stay in constant operation. Other than a couple of nuclear-powered carrier and submarines, many navy ships need to regularly align themselves together with tanker ships to renew their fuel oil, which can be challenging in rough weather condition.

In 2014, a Naval Research Laboratory group led by Heather Willauer revealed it had actually utilized a catalytic converter to extract co2 and hydrogen from seawater and after that transformed the gases into liquid hydrocarbons at a 92 percent performance rate.

Since then, the focus has actually been on increasing the performance of the procedure and scaling it approximately produce fuel in adequate amounts.

An essential action in the seawater-to-fuel conversion procedure

The co2 drawn out from seawater is very challenging to transform straight into liquid hydrocarbons with existing approaches. So, it is essential to very first transform co2 into carbon monoxide gas through the reverse water-gas shift (RWGS) response. The carbon monoxide gas can then be transformed into liquid hydrocarbons through Fischer-Tropsch synthesis.

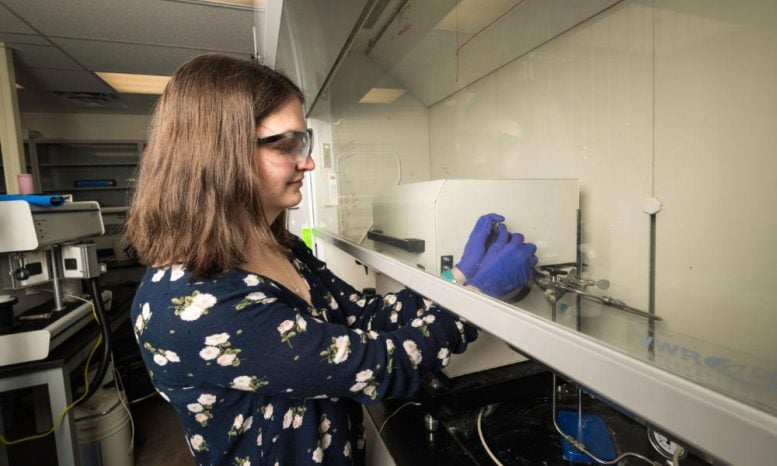

Madeline Vonglis ’20, who interned with the Porosoff research study group last summer season, carried out a number of the laboratory-scale experiments to define the potassium-promoted molybdenum carbide driver, and is 2nd author on the Energy & Environmental Science paper. She’ll start her PhD in chemical engineering this fall at Pennsylvania State University. Credit: University of Rochester / J. Adam Fenster

Typically, drivers for RWGS include pricey rare-earth elements and shut down quickly under response conditions. However, the potassium-modified molybdenum carbide driver is manufactured from inexpensive parts and did disappoint any indications of deactivation throughout constant operation of the 10-day pilot-scale research study. That’s why this presentation of the molybdenum carbide driver is necessary.

Porosoff, who initially started dealing with the job while working as a postdoctoral research study relate to Willauer’s group, found that including potassium to a molybdenum carbide driver supported on a surface area of gamma alumina might act as a low-priced, steady, and extremely selective driver for transforming co2 into carbon monoxide gas throughout RWGS.

The potassium reduces the energy barrier related to the RWGS response, while the gamma alumina—significant with grooves and pores, just like a sponge—assists guarantee that the molybdenum carbide driver particles stay dispersed, taking full advantage of the area readily available for response, Porosoff states.

To identify whether potassium-promoted molybdenum carbide may likewise work for catching and transforming co2 from power plants, the research study group will carry out more experiments to evaluate the driver’s stability when exposed to typical impurities discovered in flue gas such as mercury, sulfur, cadmium, and chlorine.

###

Reference: “Assessing the viability of K-Mo2C for reverse water–gas shift scale-up: molecular to laboratory to pilot scale” by Mitchell Juneau, Madeline Vonglis, Joseph Hartvigsen, Lyman Frost, Dylan Bayerl, Mudit Dixit, Giannis Mpourmpakis, James R. Morse, Jeffrey W. Baldwin, Heather D. Willauer and Marc D. Porosoff, 7 July 2020, Energy & Environmental Science.

DOI: 10.1039/D0EE01457E

Rochester coauthors consist of lead author Mitchell Juneau, a PhD trainee in the Porosoff research study group, and Madeline Vonglis ’20, a previous undergraduate scientist.

An Office of Naval Research award supported this job.